Inside the HNP Power Turbine: Smart Design for Maximum Efficiency

- HNP Power

- Aug 10, 2025

- 3 min read

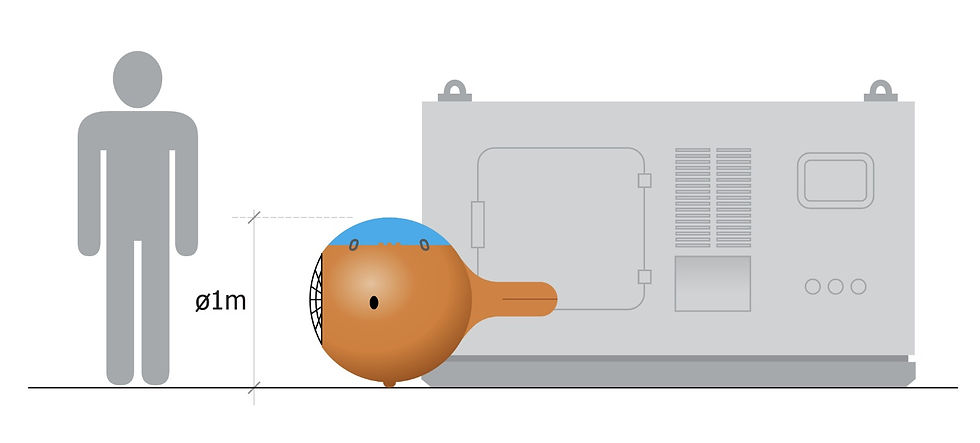

Behind the compact design of the HNP Power mini-hydropower turbine lies a robust system engineered for performance, autonomy, and resilience. While it appears minimalistic from the outside, this device incorporates a range of sophisticated technologies that allow it to function in a variety of natural water conditions, from gentle rivers to seasonal creeks. The engineering approach centers on making sustainable energy accessible, even in off-grid locations with no professional installation resources or technical expertise.

This article explores how HNP Power’s turbine works—from the internal hydraulic systems and energy conversion mechanisms to its environmental adaptability and self-positioning logic. By understanding the key components and design philosophy, it becomes clear how the system achieves such efficiency with minimal infrastructure. This is a closer look at the hardware that powers remote communities with clean, independent electricity.

How the Hydraulic Ram Pump and Kaplan Turbine Work Together

The turbine’s performance begins with its core mechanism: a combination of a hydraulic ram pump and a Kaplan radial-axial turbine. The hydraulic ram pump operates on the water hammer principle—using the kinetic energy of flowing water to build internal pressure without needing external electricity. This self-generated pressure is then routed to the turbine’s nozzles, where water is converted into rotational force.

The Kaplan-style turbine is designed specifically for low-flow, low-head conditions. Its rotary-blade system responds efficiently even to gentle streams, producing consistent energy output. This hybrid of pressure-driven pumping and low-flow rotation forms the core of the system’s ability to work in creeks, rivers, and even waterfalls without requiring a dam or reservoir. The combination ensures stable operation across various flow levels and weather conditions.

In addition, the turbine does not freeze in cold climates. Its housing and internal systems are designed to remain functional in sub-zero temperatures, making it suitable for Canada’s northern regions. The result is a compact device that can function continuously with no manual adjustments and no reliance on fossil fuels or grid connections.

Technical Features That Maximize Operational Stability

Internally, the HNP Power turbine features a fully integrated set of control and mechanical systems. The casing is made from a rugged plastic composite, resistant to corrosion and impact. Inside, the turbine shaft, generator rotor, and stator coils are assembled in a sealed chamber protected from debris and moisture. A built-in load regulation system manages energy flow, optimizing performance according to water conditions and electrical demand.

Sensors play a critical role. A water pressure sensor and water level sensor feed real-time data to the control and inverter unit, allowing the system to automatically adjust its position and load response. The turbine’s exhaust valve includes reverse protection to prevent backflow, and the electrical toggle switch is waterproof to guarantee uninterrupted power delivery.

One of the standout innovations is the automatic positioning system, which uses two anchor points and tension sensors to locate the ideal location in the river. The system dynamically adjusts the length of anchor cables until it identifies a balanced working triangle, ensuring the generator is always located in the most energy-efficient position relative to the water current. This autonomous behavior reduces maintenance and increases long-term reliability.

Scalability and Grid-Independent Applications

While one unit can provide up to 1.9 kWh—sufficient for basic household needs—the design allows for scalability. Several turbines can be connected in parallel to create a microgrid serving a neighborhood, outpost, or small village. Each turbine operates independently but can be synchronized in deployment and energy routing to meet higher demand levels.

Because the turbine requires no permanent foundations, it can be relocated or reinstalled based on seasonal conditions. In regions where water levels vary, this flexibility allows users to shift the system to another nearby location without complex planning or construction. As a result, communities are not locked into fixed infrastructure but gain an adaptable, low-cost solution that grows with their needs.

This modular approach also makes the HNP Power system ideal for hybrid setups—where solar, battery, and hydropower systems work together to provide 24/7 energy coverage. As energy demand evolves, communities can increase capacity by simply adding more units, without significant investment or training.

Smart Engineering That Empowers Remote Living

HNP Power’s mini-hydropower turbine reflects a smart balance of minimalism and engineering depth. Every component—from the blade system to the control unit—is built to serve long-term efficiency, resilience, and simplicity. There are no unnecessary parts, no complex installation procedures, and no external dependencies.

This is the kind of energy solution that meets the challenges of remote living: scalable, robust, and easy to use. With its advanced positioning logic, automated response systems, and all-weather design, the HNP Power turbine allows isolated communities to achieve energy self-sufficiency without technical barriers. It's not just an innovation in renewable energy—it’s a practical, ready-to-deploy answer to modern off-grid power demands.

Comments